工业自动化 机器人 & 仓储自动化

2022-05-19

2021年协作机器人市场反弹增长40%

MAYA XIAO

Maya在电动汽车、自动化系统和机器人领域拥有跨学科的技术背景,现担任Interact Analysis的研究经理,负责锂离子电池、叉车、工业和协作机器人市场等研究。

After a serious contraction in sales in 2020, the cobot market experienced a resounding 40% growth rebound in 2021, exceeding its 2019 market size. The period out to 2026 will see further strong expansion in sales and our forecasts show that by 2026 the cobot market will be worth over $2bn. The challenge will be for the sector to maintain growth over the longer term. How will they do this?

Logistics and services will be the long-term growth drivers

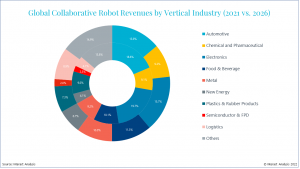

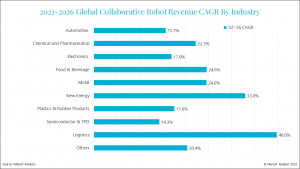

We expect the overall robotics sector to see strong year-on-year growth of around 20% out to 2030. Industries are recalibrating after the turbulence caused by the pandemic and are responding to the challenges of current labor shortages by investing heavily in automation solutions. The key to maintaining long-term growth in the cobot market will lie in diversifying the range of application scenarios and achieving scale. There are many opportunities that the cobot industry can explore, notably in the burgeoning logistics and services markets. In fact, logistics is forecast to be the fastest-growing market for cobots in the next 5 years, with revenues more than doubling, and we believe that logistics and services will be the long-term drivers of growth. There is also the potential for expansion in key existing markets such as electronics, automotive and food and beverage through the introduction of more advanced technologies.

Cobot logistics revenues will more than double in the next five years

New technologies enabling dedicated industry solutions

Collaborative robot technology is becoming more sophisticated and focused. Vendors are moving away from simply selling concepts of ‘collaboration’ or ‘safety’ and are concentrating on offering specific solutions for different user scenarios. Potential market growth in industrial manufacturing lies in the development of high-precision sensors, machine vision, end arm tools and safety control software, enabling flexible production and cooperation between humans and robots.

These more advanced technologies when applied to collaborative robots offer the potential to replace or assist manual work in the completion of pick and place, packaging, quality inspection and other operations. Where the services sector is concerned, advances in machine vision and machine learning technology are opening new opportunities for the deployment of cobots in education, medical care, retail, logistics and catering. Making serious incursions into these service industries will be key to the long-term future market success of the cobot sector.

Cobots are making inroads into the industrial space

Cobots will struggle in industries where there are higher speed and accuracy requirements, (‘services’ is included in ‘others’)

We predict that by 2025 collaborative robots will account for ~10% of total industrial robot sales. There are certain sectors of the industrial robot market where cobots will fail to make any significant penetration. These include areas where there are higher speed and accuracy requirements and where there is no human interaction. Automotive is a typical case in point. There is already a very high level of mature automation solutions in this industry, for instance in body shops for welding tasks and final painting. Traditional industrial robots will maintain their high-level presence in these scenarios, but opportunities do exist for collaborative robots to grow their presence in automotive.

Universal Robots, for instance, offers cobots with functionality in the powertrains, electronics, and interiors production stages, including machine tending, inspection, and assembly. Finally, industrial SMEs, which generally produce smaller batches of customized products, have tended to find traditional industrial robots too expensive. This is not the case with cobots and so SMEs represent a totally new industrial robot market opportunity that is open only to cobots.

To continue the conversation about collaborative robots, get in touch with Maya directly: Maya.Xiao@InteractAnalysis.com

最新工业自动化洞察

2025年全球工业机器人出货量有望复苏

Li-Cycle倒下,电池回收市场将走向何方

锂电池市场:产能规划与出货预期更新

最新机器人&仓储自动化洞察

2025年全球工业机器人出货量有望复苏

人形机器人核心硬件的发展现状和趋势